Automatic Tool Changer(ATC) is composed of tool magazine and tool changing arms. Automatic too changer is installed separately from machine tool with the purpose of preventing adverse influences of vibration during running of automatic tool changer and other reasons on precision. Tool selection adopts the method of fixed address in the shortest path. All tools return to original position, therefore, the problem of collision between large-size tools is only considered in initial installation. Two-way tool magazine adopts the shortest path.

| Standard Configuration | Optional Configuration |

| Vertical Type | |

| FANUC CNC system | FANUC/Siemens/Heidenhain CNC Controller |

| BT40 8000rpm Spindle | BT/ISO/HSK-A63 10000~30000rpm Spindle |

| Spindle Belt Drive | Spindle Direct Drive |

| Spindle Oil Chiller | |

| Spindle coolant nozzle system | Coolant Through Spindle (CTS) |

| High Precision Screw rod | Coolant Through Screw rod |

| XYZ Axis Linear rails | |

| XYZ Axis Servo Motor | |

| Fully Enclosed Splash Guard | |

| Electrical Cabinet Heat Exchanger | Electrical Cabinet AC |

| Handheld air gun | |

| Water gun | |

| Automatic lubrication system | |

| LED working lamp | |

| Tool magazine | ATC/Tool Magazine system |

| CNC Manual & Operation | |

| Chip flush coolant system | |

| LCD | |

| Working lamp | |

| Three-color warning lamp | |

| Transformer(According to Local Voltage) | |

| Took kit | |

| The 4th axis rotary table | |

| spiral type Chip Conveyor system | |

| Chain type Chip Conveyor system | |

| Linear Scale | |

| Auto.Tool Measuring system | |

| Auto.Workpiece Measuring system | |

| CE Mark | |

| Others Options as requested |

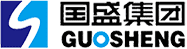

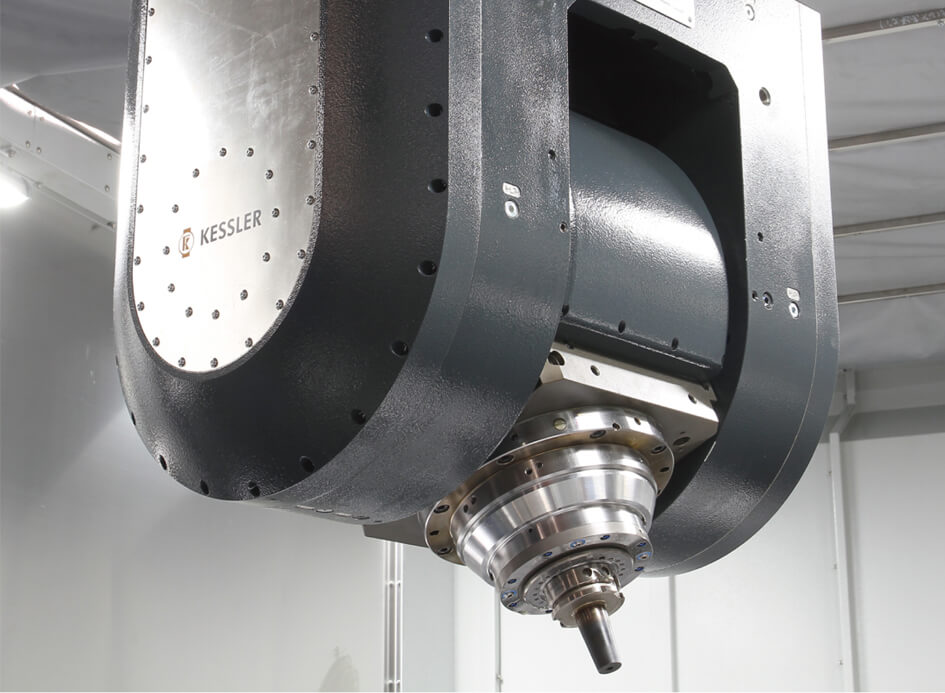

German KESSLER AC swinging head

German KESSLER AC swinging head

German HEIDENHAIN TNC640 system

German HEIDENHAIN TNC640 system

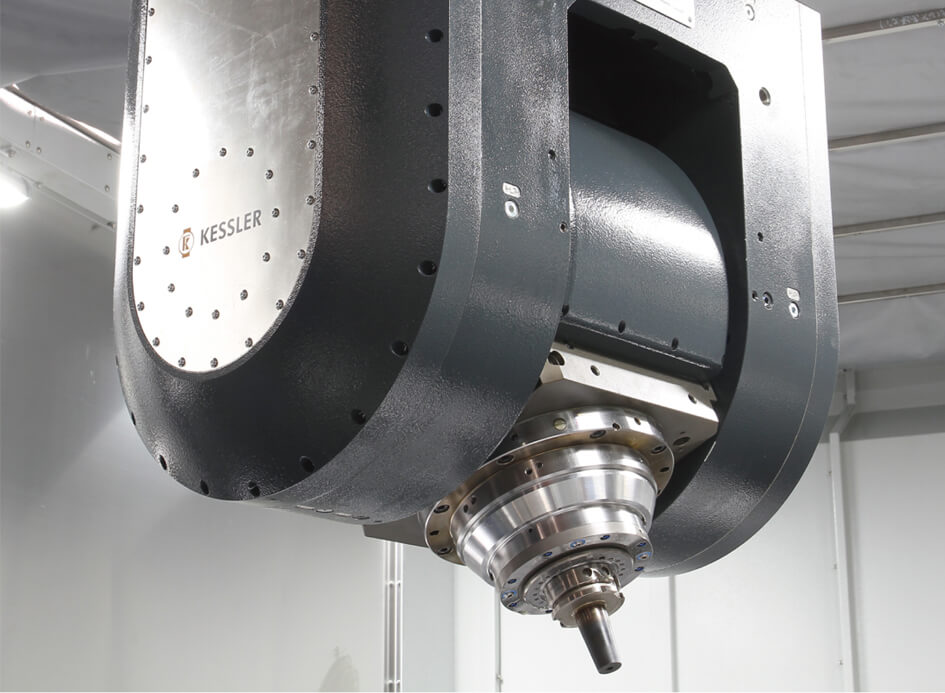

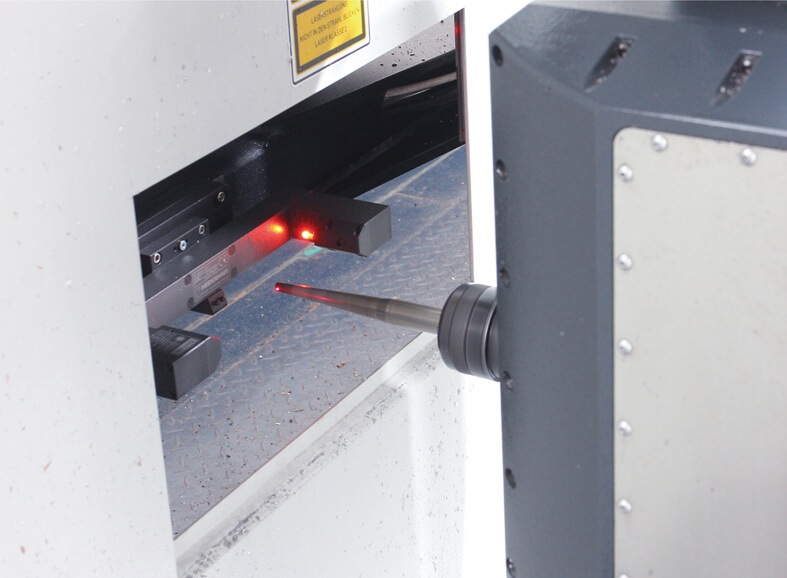

Laser tool setting instrument

Laser tool setting instrument

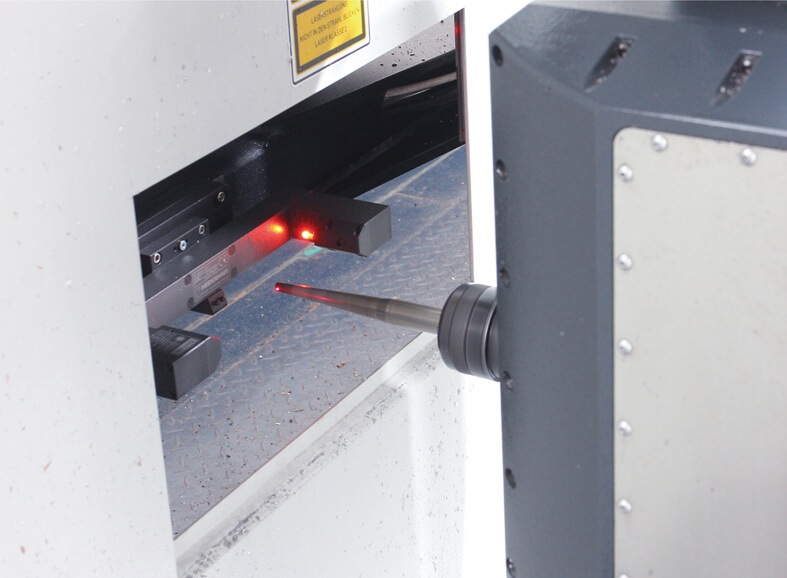

Automatic chip removing device

Automatic chip removing device

Tool Magazine

Tool Magazine

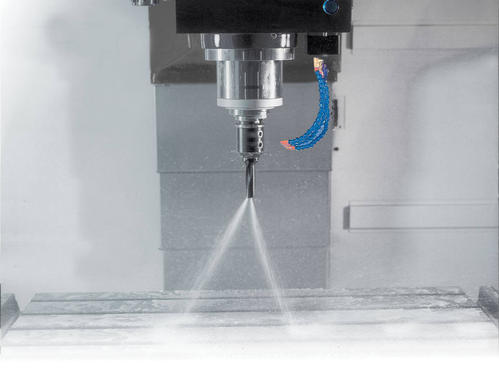

Coolant Through Spindle (CTS)optional

Because of the cold inside the hollow spindle coolant spewing from the tools, can directly effect on the workpiece and cutting tool parts, cooling effect is better than ordinary spindle, make better surface quality of machined part.

-

Parameter table

Bridge Type 5-axis Gantry Machining Center Specifications 16 Series Machine type GMB2516LX Worktable Worktable size mm 1950×2700 Worktable load T 20 Worktable T-slot 7-22×285 Processing scope Gantry width mm 1800 Triaxial itinerary X/Y/Z mm 2500×1600×800 Distance from spindle nose to table surface mm 210-1010 Spindle AC head Kessler Max. rotating speed of spindle rpm 18000 Spindle taper bore type HSK-A63 A-axis swing angle ±105° C-axis swing angle ±360° Main motor power kW S1:56,S6:70 Maximum torque of spindle Nm S1:90,S6:110 Drive feed Fast Feed Speed (X/Y/Z) m/min 15/20/20 Accuracy of machine tools Positioning accuracy (X/Y/Z) mm 0.013/0.008/0.007 Repeated positioning accuracy (X/Y/Z) mm 0.006/0.006/0.006 Other Weight T 50 Total power capacity KVA 92 Overall dimension (about) mm 6000×6000×5200 -

German KESSLER AC swinging head

German KESSLER AC swinging head

-

German HEIDENHAIN TNC640 system

German HEIDENHAIN TNC640 system

-

Laser tool setting instrument

Laser tool setting instrument

-

Automatic chip removing device

Automatic chip removing device

-

Tool Magazine

Tool Magazine

Automatic Tool Changer(ATC) is composed of tool magazine and tool changing arms. Automatic too changer is installed separately from machine tool with the purpose of preventing adverse influences of vibration during running of automatic tool changer and other reasons on precision. Tool selection adopts the method of fixed address in the shortest path. All tools return to original position, therefore, the problem of collision between large-size tools is only considered in initial installation. Two-way tool magazine adopts the shortest path.

-

Coolant Through Spindle (CTS)optional

Because of the cold inside the hollow spindle coolant spewing from the tools, can directly effect on the workpiece and cutting tool parts, cooling effect is better than ordinary spindle, make better surface quality of machined part.

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu