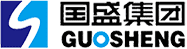

On the rigid and attenuating large bed, the sturdy box type column is arranged. The wide angle sliding Box Way is adopted on the X and Z axis, which has high rigidity and high reliability structure.

| Standard Configuration | Optional Configuration |

| Ivt Vertical lathe | |

| FANUC CNC system | FANUC/Siemens/Heidenhain CNC Controller |

| BT40 12000rpm Spindle | BT/ISO/HSK-A63 10000~30000rpm Spindle |

| Spindle Direct Drive | |

| Spindle Oil Chiller | |

| Spindle coolant nozzle system | Coolant Through Spindle (CTS) |

| High Precision Screw rod | Coolant Through Screw rod |

| XYZ Axis Linear rails | |

| XYZ Axis Servo Motor | |

| Fully Enclosed Splash Guard | |

| Electrical Cabinet Heat Exchanger | Electrical Cabinet AC |

| Handheld air gun | |

| Water gun | |

| Automatic lubrication system | |

| LED working lamp | |

| Tool magazine | ATC/Tool Magazine system |

| CNC Manual & Operation | |

| Chip flush coolant system | |

| LCD | |

| Working lamp | |

| Three-color warning lamp | |

| Transformer(According to Local Voltage) | |

| Took kit | |

| The 4th axis rotary table | |

| spiral type Chip Conveyor system | |

| Chain type Chip Conveyor system | |

| Linear Scale | |

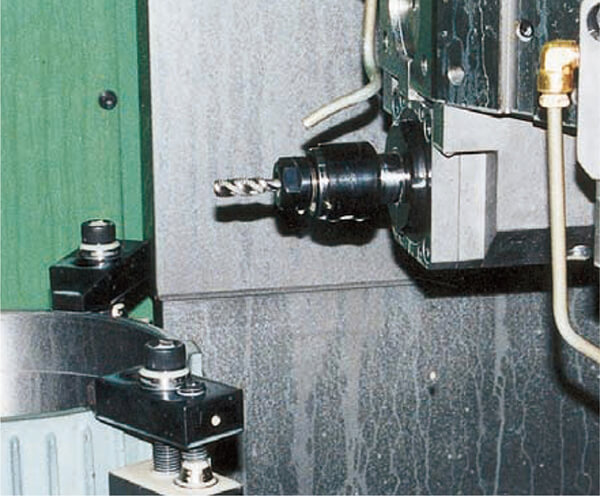

| Auto.Tool Measuring system | |

| Auto.Workpiece Measuring system | |

| CE Mark | |

| Others Options as requested |

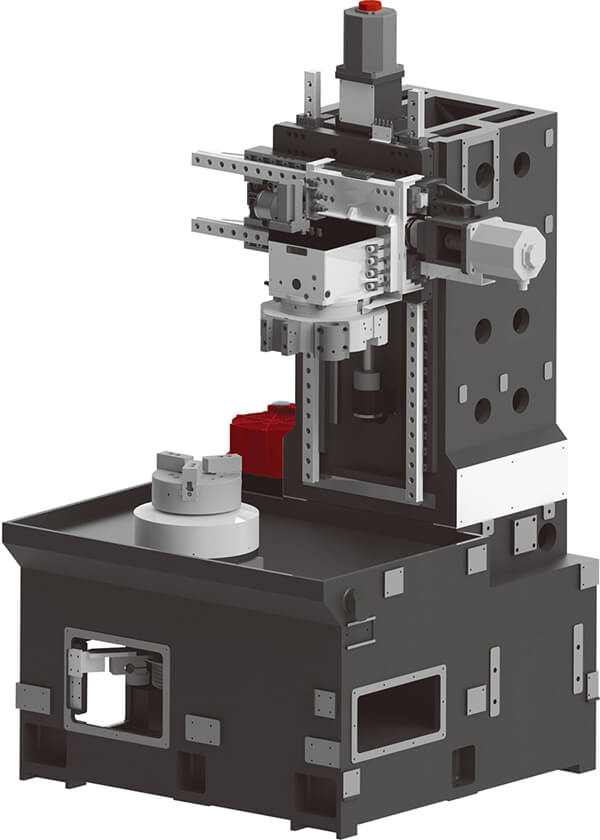

High Rigid Structure

High Rigid Structure

Linear guide and Box slide ways

Linear guide and Box slide ways

Z Axis adopts high rigid linear guide or Box slide way, ensure the stability while heavy duty machining.

Precision stability

Precision stability

Since the processed workpiece is in close contact with the chuck datum plane under the action of dead weight, it can be processed with high precision and stability from thin workpiece to large diameter and heavy workpiece.

Easy and stable clamping can also be carried out for the special-shaped workpiece with difficult clamping operation. The fixture structure is simplified and the fixture cost is reduced.

Scrapping

Scrapping

The combination surface of base and column, slide board, spindle stand, turret and bearing seat are all manually scrapping to achieve maximum assembly accuracy, structural rigidity and load balancing.

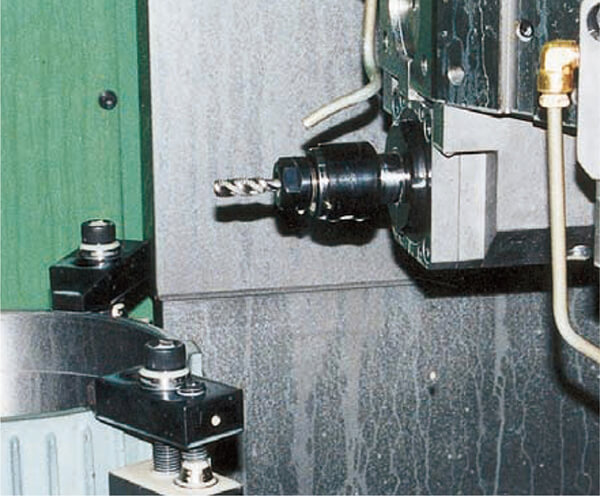

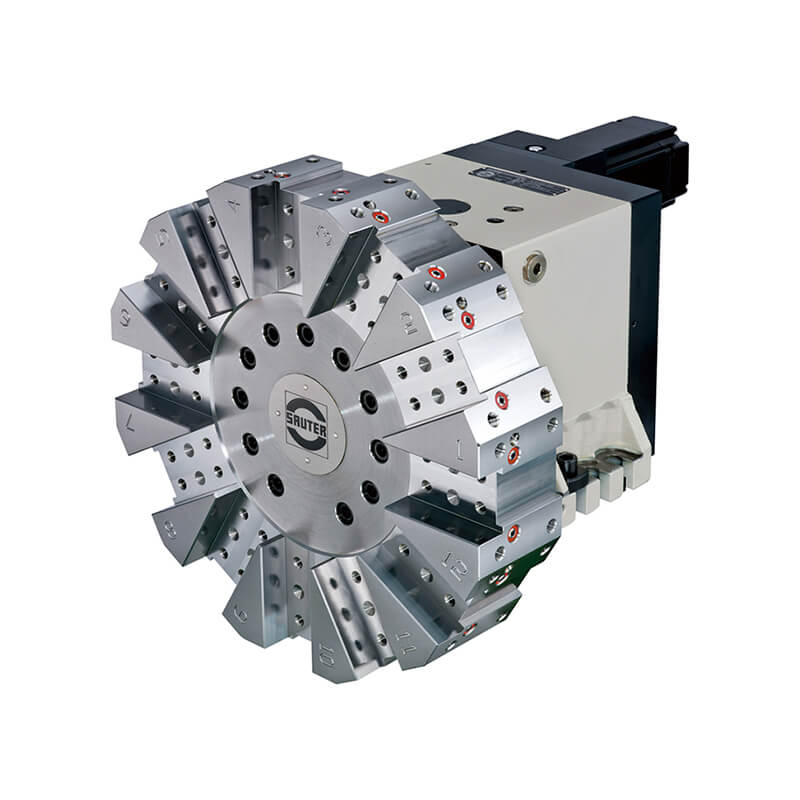

Multi-function turret flexible application

Multi-function turret flexible application

8 or 12 tool station servo turret is equipped with hydraulic system clamping, which can provide high tool changing accuracy and high rigidity. Vertical turret, horizontal turret, Gang type turret and power turret are optional.

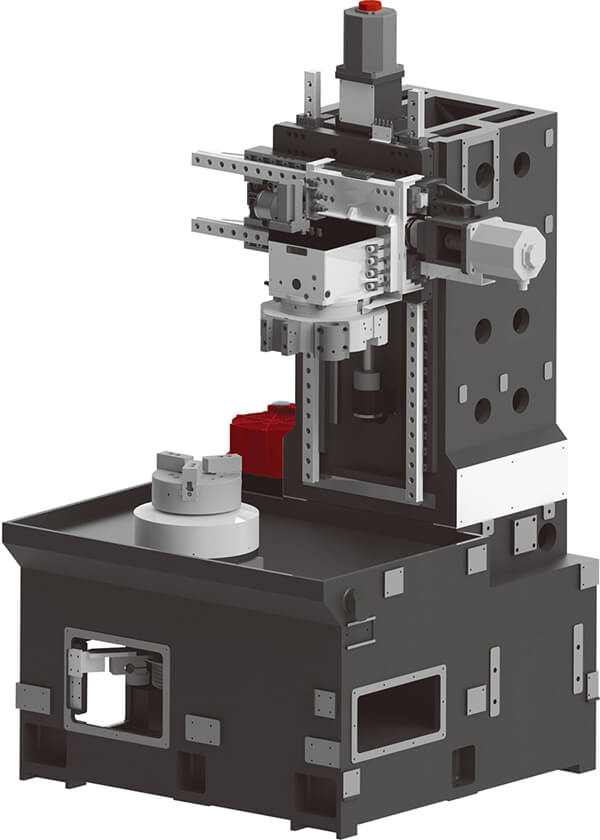

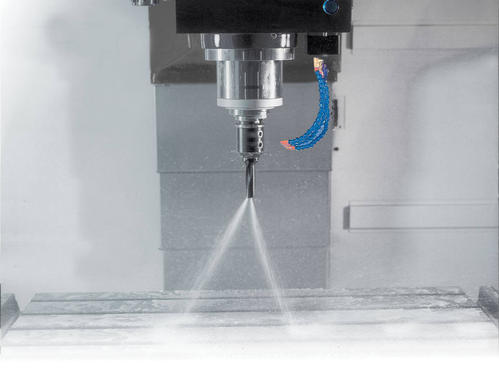

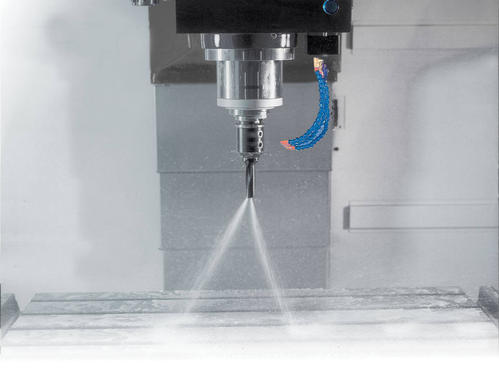

Coolant Through Spindle (CTS)optional

Because of the cold inside the hollow spindle coolant spewing from the tools, can directly effect on the workpiece and cutting tool parts, cooling effect is better than ordinary spindle, make better surface quality of machined part.

-

Parameter table

iVT 600 iVT 800 Working area Chuck diameter mm 308(12″)opt 381(15″) 381(15″)opt 450(18″) Maximum swing over base mm 650 1000 Max. machining diameter mm 600 800 Max. machining length mm 520 840 Max. load capacity kg 570(1050) 1160(2500) Spindle Max. spindle speed rpm 2500 2000 Spindle head A2-8 A2-11 Inner diameter of spindle bearing mm 130 200 Spindle bearing lubricants Grease Grease Guide lubrication Lubricating oil Lubricating oil Speed range rpm 25~2500 25~2000 Travel Travel Z mm 550 840 Travel X mm 340 450 Feed Rapid traverse X/Z axis m/min 20 20 X/Z axle ball screw Φ40*P10 Φ40*P10/Φ50*P10 Type of guide track Line rail Hard rail Guide width mm 45 Drive motor Spindle power kW 15/18.5 18.5/22 X axis power kW 3 4 Z axis power kW 3 4 Measuring system X / Z axies measuring system Absolute rotative Absolute rotative Max. positioning (X / Z) mm 0.008/0.008 0.008/0.008 Repeatability (X / Z) mm 0.005/0.005 0.005/0.005 Tool attachments Servo turret Slot type Slot type No. of tool stations 8 8 Tool size 25 32 Size of inner diameter tool mm 40 50 Changing time s 0.51 0.6 Driven tool turret BMT 65 / VDI 40 / VDI 50 BMT 75 / VDI 60 No. of tool stations # 12 12 Tool size 25/32 32 Size of inner diameter tool mm 40 50 Driven tool speed rpm 4000 4000 Driven tool power kW 4.5 5.5 Driven tool torque Nm 63 100 Electrical specifications Voltage V 380±10% 380±10% Frequency Hz 50 ± 1% 50 ± 1% Max. installed power KVA 40 80 400V line protective fuse A 100 100 400V line circuit breaker A 80 80 Connecting cable part mm2 4 x 10 4 x 10 Hydraulic unit Max. working pressure bar 55 55 Pump flow I/ min 24 24 Noise level Noise level dB (A) ≤80 ≤80 Control system FANUC 0iTF 0iTF Others Net weight kg About 6000 About 12000 Material of base Cast iron HT300 Cast iron HT300 -

High Rigid Structure

High Rigid Structure

On the rigid and attenuating large bed, the sturdy box type column is arranged. The wide angle sliding Box Way is adopted on the X and Z axis, which has high rigidity and high reliability structure.

-

Linear guide and Box slide ways

Linear guide and Box slide ways

Z Axis adopts high rigid linear guide or Box slide way, ensure the stability while heavy duty machining.

-

Precision stability

Precision stability

Since the processed workpiece is in close contact with the chuck datum plane under the action of dead weight, it can be processed with high precision and stability from thin workpiece to large diameter and heavy workpiece.

Easy and stable clamping can also be carried out for the special-shaped workpiece with difficult clamping operation. The fixture structure is simplified and the fixture cost is reduced.

-

Scrapping

Scrapping

The combination surface of base and column, slide board, spindle stand, turret and bearing seat are all manually scrapping to achieve maximum assembly accuracy, structural rigidity and load balancing.

-

Multi-function turret flexible application

Multi-function turret flexible application

8 or 12 tool station servo turret is equipped with hydraulic system clamping, which can provide high tool changing accuracy and high rigidity. Vertical turret, horizontal turret, Gang type turret and power turret are optional.

-

Coolant Through Spindle (CTS)optional

Because of the cold inside the hollow spindle coolant spewing from the tools, can directly effect on the workpiece and cutting tool parts, cooling effect is better than ordinary spindle, make better surface quality of machined part.

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu