Large Gantry Cnc Machines

Sticking to the belief of "Creating products of high quality and making friends with people from all over the world", we always put the interest of customers in the first place for Large Gantry Cnc Machines, Deckel Cnc Milling Machine , Laser Cnc Machine , Prolight Machining Center , We are seeking for extensive cooperation with honest customers, achieving a new cause of glory with customers and strategic partners. Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for Large Gantry Cnc Machines, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

-

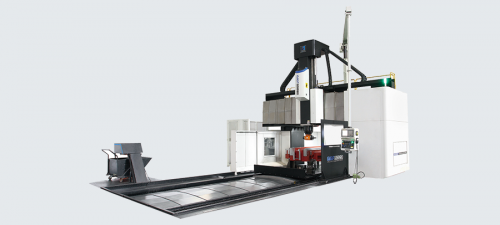

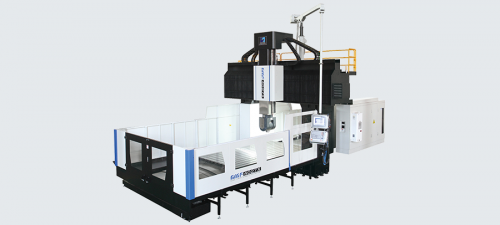

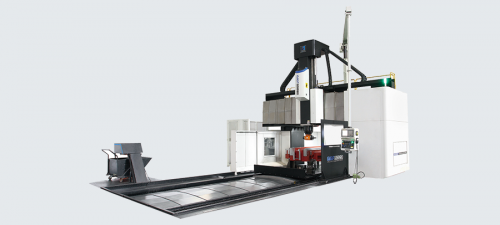

GMS DIE AND MOLD MACHINING CENTER

By means of the modern structure design methods combining the mechanical design and finite element method design, and integrating the whole machine’s thermogenic management technology and ergonomics engineering design technology, the whole machine reaches the characteristics of high rigidity, high electric rigidity, high reliability and excellent thermal stability, etc,

-

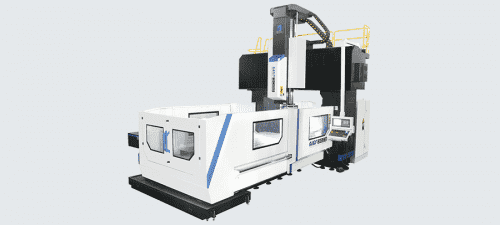

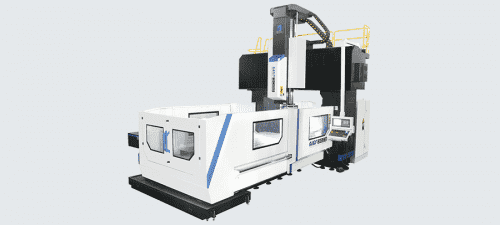

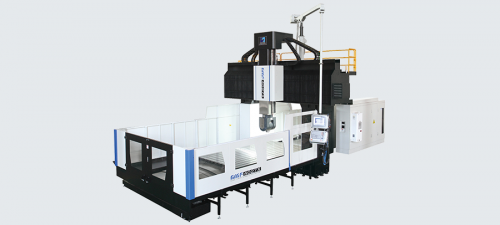

GMF GENERAL GANTRY MACHINING CENTER

Widely used in the aviation, auto, precision molding industries, GMF series can provide a high-performance mechanical system and a software interface which can be operated easily. This provides multiple choices of multiple choices that will allow you to fully realize the high precision dream.

-

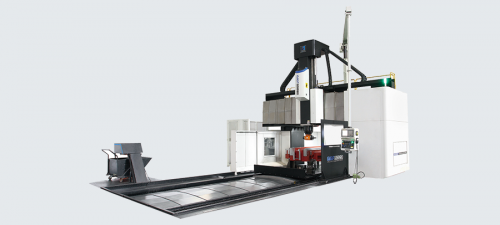

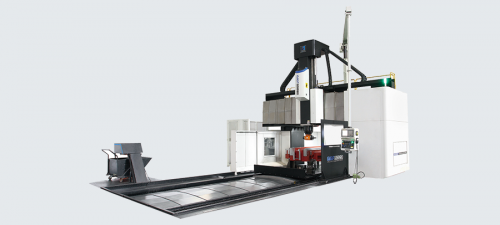

GMF 5-FACE GANTRY MACHINING CENTER

Roller-type linear rolling guide has high rigidity and high precision, which is suitable for heavy cutting.

Z axis adopts four-track or square sleeper structure, which is convenient for customers to select machine tools. Four-track is suitable for high-speed processing, and square sleeper is suitable for high-rigidity processing.

-

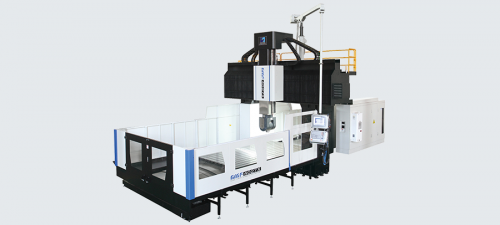

GMF 5-AXES GANTRY MACHINING CENTER

5-axis linkage and full-closed loop control ensure it is suitable for processing complex surfaces of precision molds.

The Z axis four wire rail structure has small friction resistance and good accuracy.

With German KESSLER AC swinging head and tuning fork type structure, AC axles are driven by torque motor.

-

GMB 5-AXES GANTRY MACHINING CENTER

5-axis linkage and full-closed loop control ensure it is suitable for processing complex surfaces of precision molds.

Z oriented box in box type symmetric structure ensures balanced cutting stress, and slight thermal deformation.

Screw hollow cooling effectively restrains thermal extension.

-

-

-

-

-