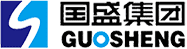

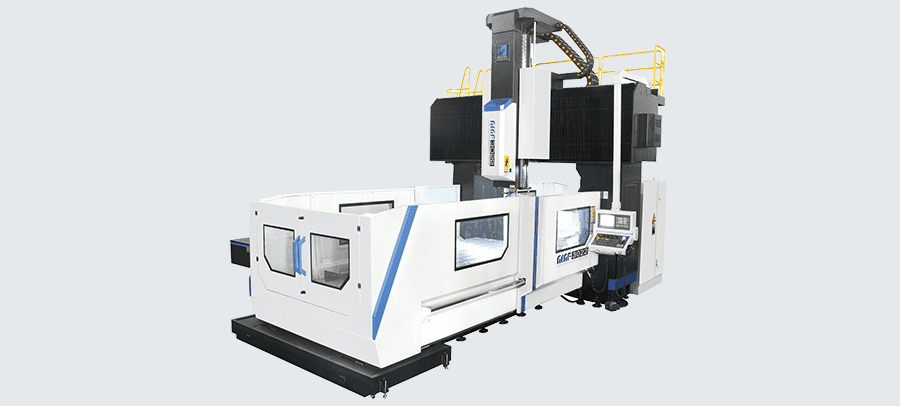

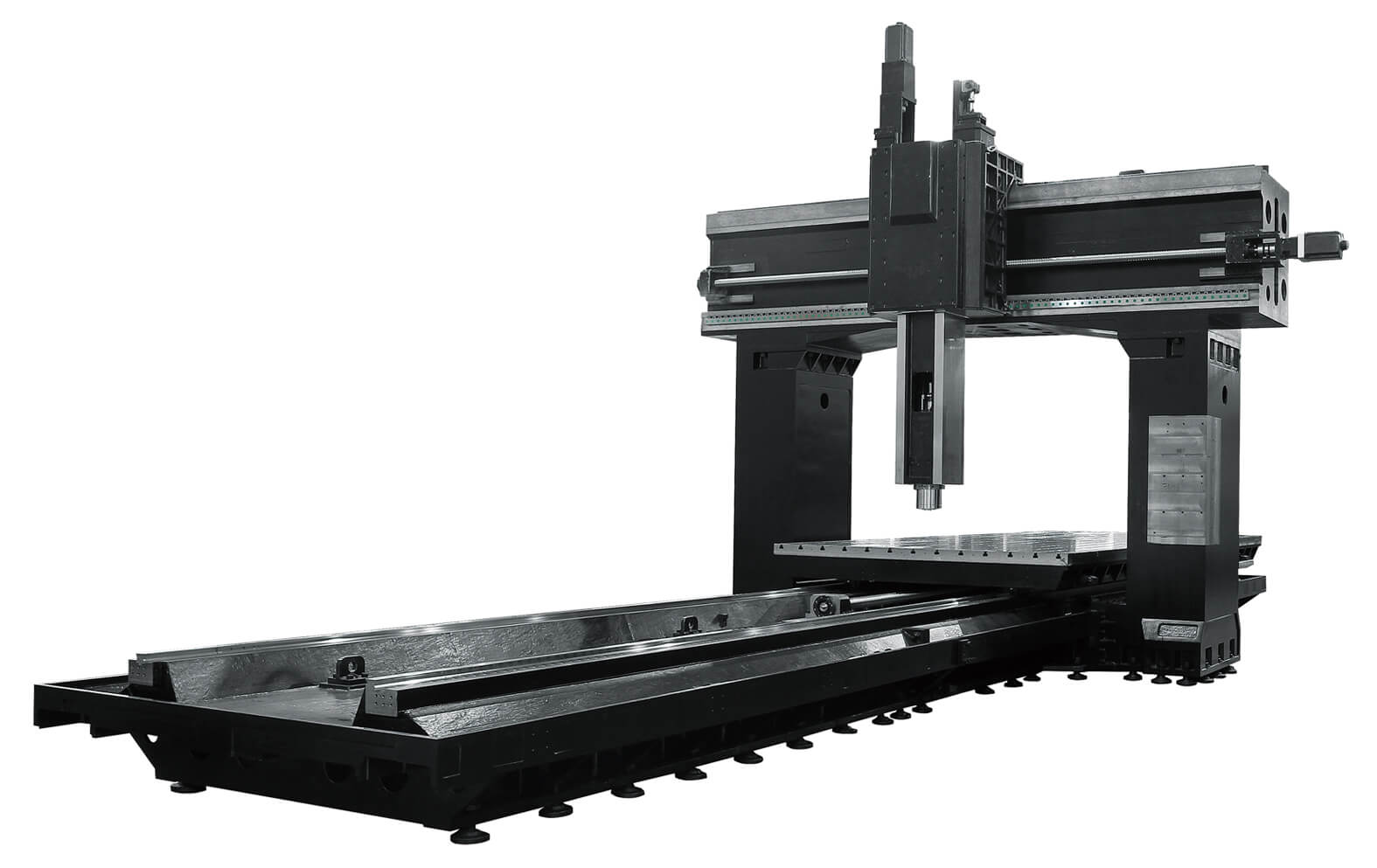

The structure of machine tool is analyzed with finite element analysis at all stages from foundation design to guarantee of high-speed and high-precision continuous machining. A simulation test for deformation produced when the center of machine tool bears load is conducted to guarantee excellent bending rigidity of machine tool.

| Standard Configuration | Optional Configuration |

| Vertical Type | |

| FANUC CNC system | FANUC/Siemens/Heidenhain CNC Controller |

| BT40 8000rpm Spindle | BT/ISO/HSK-A63 10000~30000rpm Spindle |

| Spindle Belt Drive | Spindle Direct Drive |

| Spindle Oil Chiller | |

| Spindle coolant nozzle system | Coolant Through Spindle (CTS) |

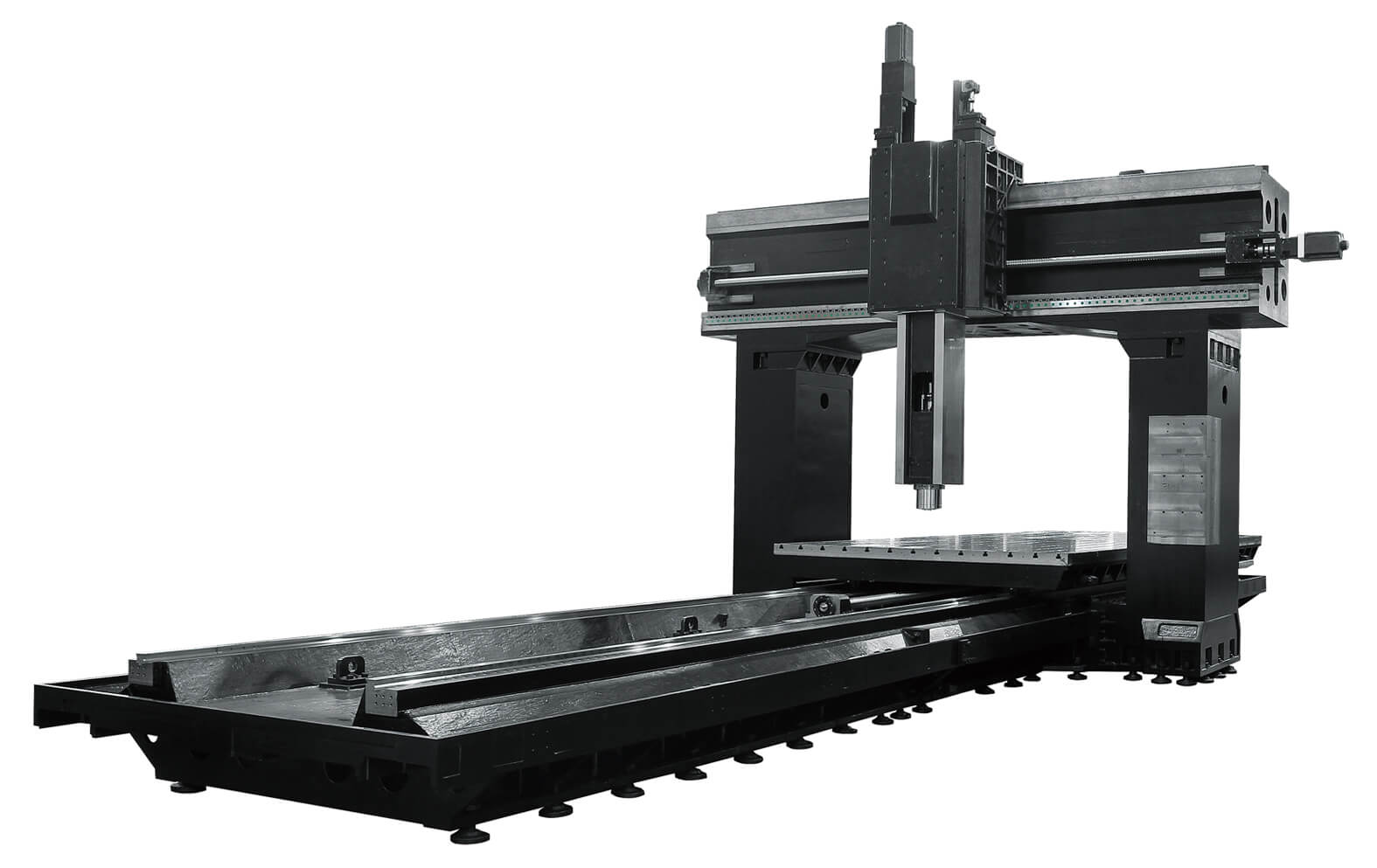

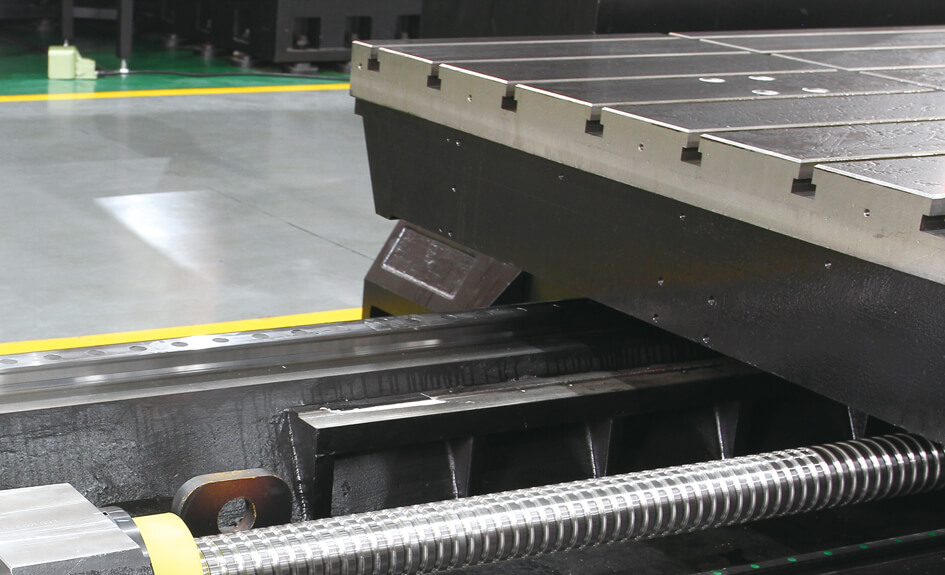

| High Precision Screw rod | Coolant Through Screw rod |

| XYZ Axis Linear rails | |

| XYZ Axis Servo Motor | |

| Fully Enclosed Splash Guard | |

| Electrical Cabinet Heat Exchanger | Electrical Cabinet AC |

| Handheld air gun | |

| Water gun | |

| Automatic lubrication system | |

| LED working lamp | |

| Tool magazine | ATC/Tool Magazine system |

| CNC Manual & Operation | |

| Chip flush coolant system | |

| LCD | |

| Working lamp | |

| Three-color warning lamp | |

| Transformer(According to Local Voltage) | |

| Took kit | |

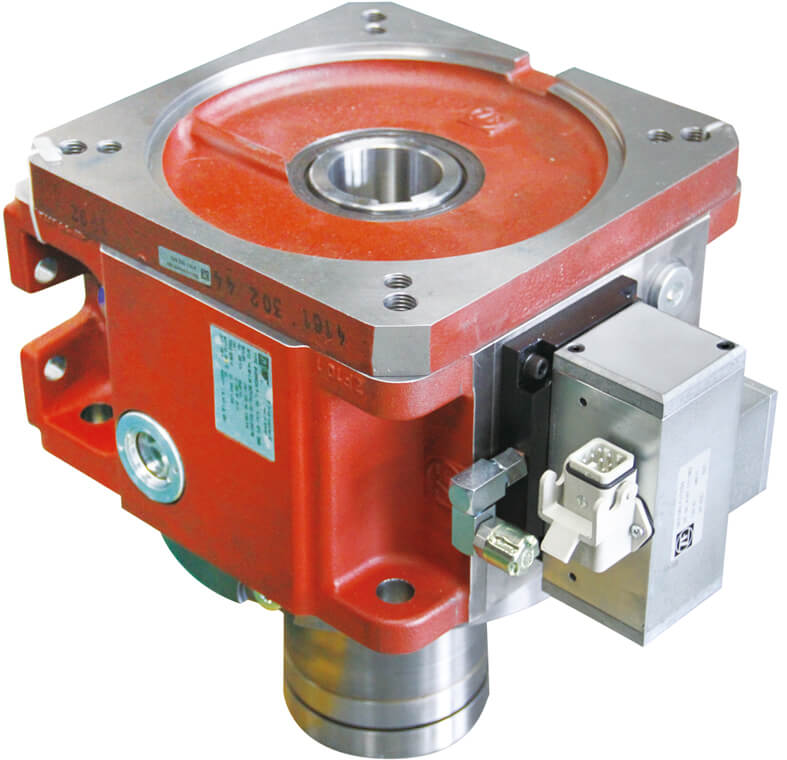

| The 4th axis rotary table | |

| spiral type Chip Conveyor system | |

| Chain type Chip Conveyor system | |

| Linear Scale | |

| Auto.Tool Measuring system | |

| Auto.Workpiece Measuring system | |

| CE Mark | |

| Others Options as requested |

High Rigidity

High Rigidity

Optional grating ruler realizes closed loop control.

Optional grating ruler realizes closed loop control.

Double slip pillow standard double speed gear box, Increase spindle output torque

Double slip pillow standard double speed gear box, Increase spindle output torque

90 degree horizontal milling head

CNC system

CNC system

Interpolation: the backlash interpolation, quadrant error interpolation, tool length interpolation, tool radius interpolation, temperature interpolation (optional).

Feed function: feed rate trimming, feeding rate per minute per rotation, feed rate, programmable acceleration limit.

Spindle function: spindle speed, spindle override function trimming, spindle orientation quasi stop, speed limit.

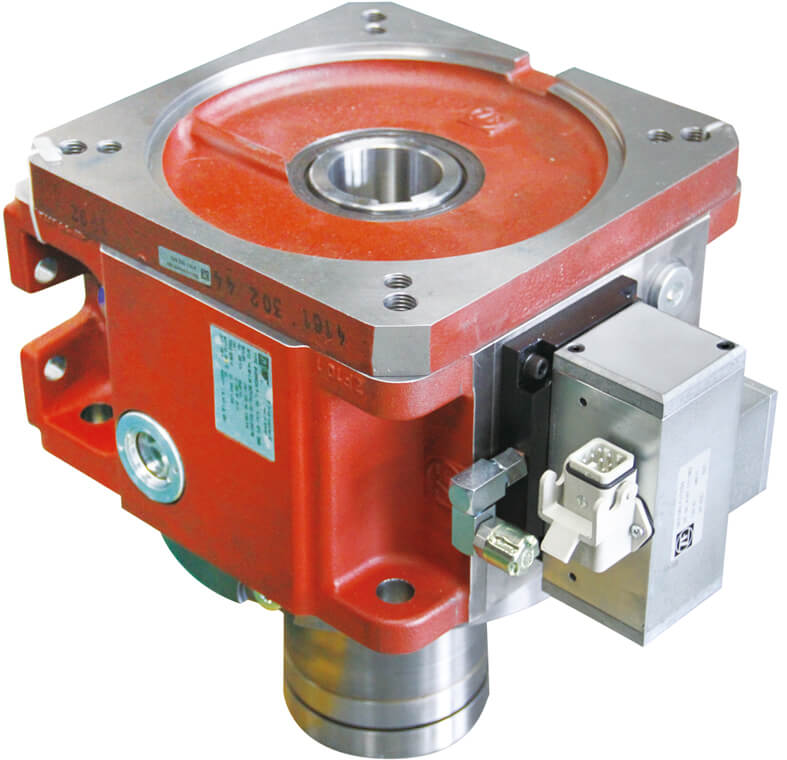

Tool Magazine

Tool Magazine

Automatic Tool Changer(ATC) is composed of tool magazine and tool changing arms. Automatic too changer is installed separately from machine tool with the purpose of preventing adverse influences of vibration during running of automatic tool changer and other reasons on precision. Tool selection adopts the method of fixed address in the shortest path. All tools return to original position, therefore, the problem of collision between large-size tools is only considered in initial installation. Two-way tool magazine adopts the shortest path.

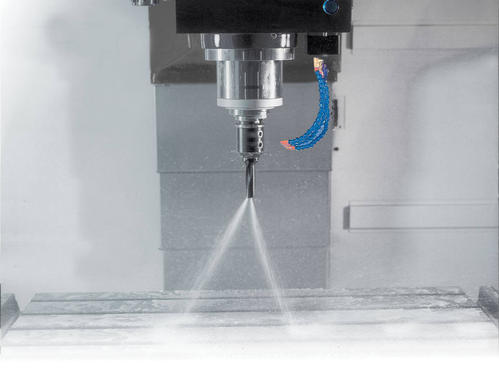

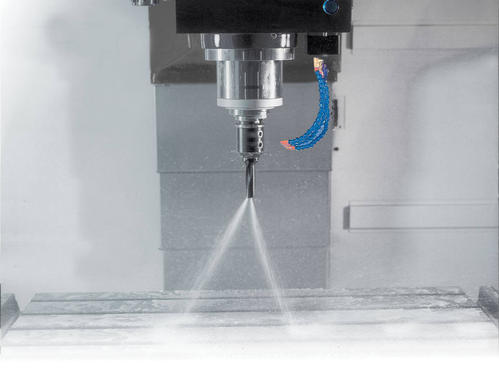

Coolant Through Spindle (CTS)optional

Because of the cold inside the hollow spindle coolant spewing from the tools, can directly effect on the workpiece and cutting tool parts, cooling effect is better than ordinary spindle, make better surface quality of machined part.

-

Parameter table

Specifications 13 Series 15 Series 18 Series Machine Type Two line and one hard Unit GMF2213T GMF2713T GMF2215T GMF2715T GMF3215T GMF2518T GMF3018T Three line rail GMF2213L GMF2713L GMF2215L GMF2715L GMF3215L GMF2518L GMF3018L Worktable Worktable size mm 2200×1100 2700×1100 2200×1300 2700×1300 3200×1300 2500×1500 3000×1500 Worktable load T 6 8 6 8 8 10 12 Worktable T-slot 7-22×150 7-22×175 9-22×160 Processing scope Gantry width mm 1300 1500 1800 Triaxial itinerary X/Y/Z mm 2000/1300/900 2500/1300/900 2000/1500/900 2500/1500/900 3000/1500/900 2500/1800/900 3000/1800/900 Distance from spindle nose to table surface mm 180-1080 150-1050 180-1080 150-1050 150-1050 150-1050 Drive feed Fast feed speed(X/Y/Z) m/min 15/15/10 15/15/10 12/15/10 15/15/10 12/15/10 Spindle Tool holder specification BT50 BT50 BT50 Spindle speed rpm 6000 6000 6000 Main motor power kW 15/18.5 15/18.5 22/26 Maximum torque of spindle Nm 295(Belt)/940(ZF) 295(Belt)/940(ZF) 250(Belt)/795(ZF) Tool magazine(Optional configuration) Tool magazine capacity 24 24 24 Maximum tool diameter(Full Tool/Vacancy) mm 100/200 100/200 100/200 Maximum tool length mm 300 300 300 Maximum tool weight kg 15 15 15 Accuracy of machine tools Positioning accuracy X mm 0.016 0.016 0.02 0.016 0.02 Y mm 0.016 0.016 0.02 0.016 0.02 Z mm 0.016 0.016 0.016 0.016 0.016 Repeated positioning accuracy X mm 0.012 0.012 0.012 0.012 0.012 Y mm 0.012 0.012 0.012 0.012 0.012 Z mm 0.01 0.01 0.01 0.01 0.01 Other Machine tool weight T 18 20 19 21 23 22 24 Total power capacity KVA 55 55 55 -

High Rigidity

High Rigidity

The structure of machine tool is analyzed with finite element analysis at all stages from foundation design to guarantee of high-speed and high-precision continuous machining. A simulation test for deformation produced when the center of machine tool bears load is conducted to guarantee excellent bending rigidity of machine tool.

-

Optional grating ruler realizes closed loop control.

Optional grating ruler realizes closed loop control.

-

Double slip pillow standard double speed gear box, Increase spindle output torque

Double slip pillow standard double speed gear box, Increase spindle output torque

90 degree horizontal milling head

-

CNC system

CNC system

Interpolation: the backlash interpolation, quadrant error interpolation, tool length interpolation, tool radius interpolation, temperature interpolation (optional).

Feed function: feed rate trimming, feeding rate per minute per rotation, feed rate, programmable acceleration limit.

Spindle function: spindle speed, spindle override function trimming, spindle orientation quasi stop, speed limit.

-

Tool Magazine

Tool Magazine

Automatic Tool Changer(ATC) is composed of tool magazine and tool changing arms. Automatic too changer is installed separately from machine tool with the purpose of preventing adverse influences of vibration during running of automatic tool changer and other reasons on precision. Tool selection adopts the method of fixed address in the shortest path. All tools return to original position, therefore, the problem of collision between large-size tools is only considered in initial installation. Two-way tool magazine adopts the shortest path.

-

Coolant Through Spindle (CTS)optional

Because of the cold inside the hollow spindle coolant spewing from the tools, can directly effect on the workpiece and cutting tool parts, cooling effect is better than ordinary spindle, make better surface quality of machined part.

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu