Gantry Cnc Boring Machine

No matter new shopper or old customer, We believe in very long expression and dependable relationship for Gantry Cnc Boring Machine, Micro Cnc Milling Machine , Aluminium Milling Machine , Micro Cnc Machine , We persistently develop our enterprise spirit "quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first. Our items are commonly identified and trusted by people and can fulfill repeatedly altering economic and social wants of Gantry Cnc Boring Machine, Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

-

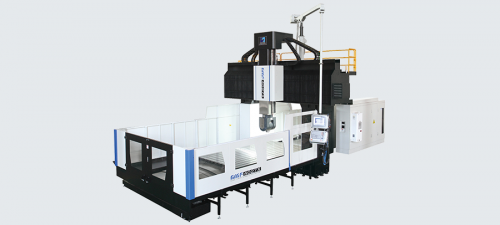

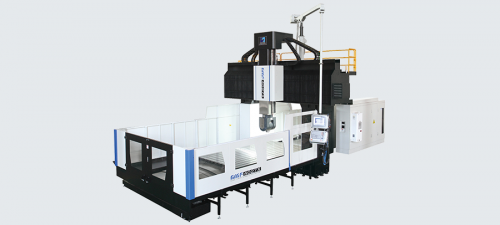

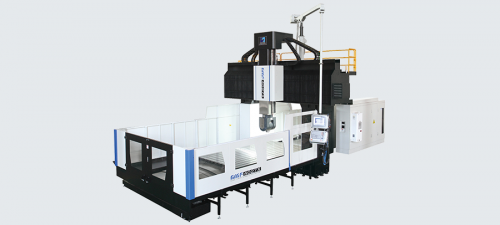

GMS DIE AND MOLD MACHINING CENTER

By means of the modern structure design methods combining the mechanical design and finite element method design, and integrating the whole machine’s thermogenic management technology and ergonomics engineering design technology, the whole machine reaches the characteristics of high rigidity, high electric rigidity, high reliability and excellent thermal stability, etc,

-

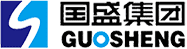

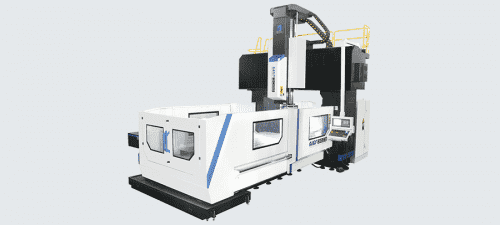

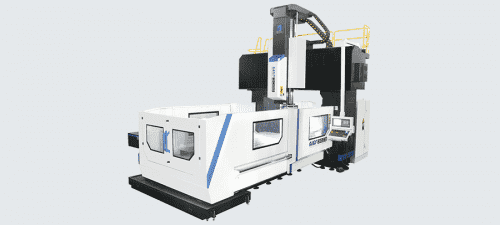

GMF GENERAL GANTRY MACHINING CENTER

Widely used in the aviation, auto, precision molding industries, GMF series can provide a high-performance mechanical system and a software interface which can be operated easily. This provides multiple choices of multiple choices that will allow you to fully realize the high precision dream.

-

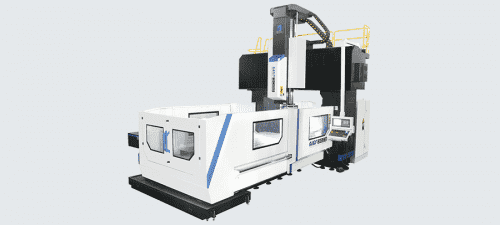

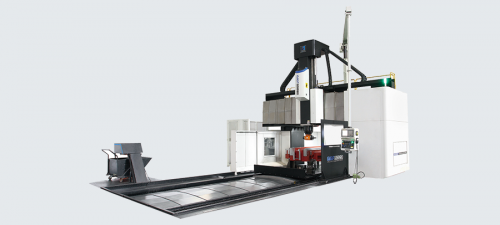

GMF 5-FACE GANTRY MACHINING CENTER

Roller-type linear rolling guide has high rigidity and high precision, which is suitable for heavy cutting.

Z axis adopts four-track or square sleeper structure, which is convenient for customers to select machine tools. Four-track is suitable for high-speed processing, and square sleeper is suitable for high-rigidity processing.

-

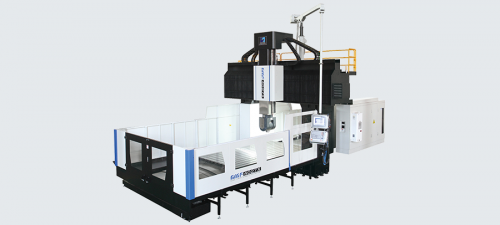

GMF 5-AXES GANTRY MACHINING CENTER

5-axis linkage and full-closed loop control ensure it is suitable for processing complex surfaces of precision molds.

The Z axis four wire rail structure has small friction resistance and good accuracy.

With German KESSLER AC swinging head and tuning fork type structure, AC axles are driven by torque motor.

-

GMB 5-AXES GANTRY MACHINING CENTER

5-axis linkage and full-closed loop control ensure it is suitable for processing complex surfaces of precision molds.

Z oriented box in box type symmetric structure ensures balanced cutting stress, and slight thermal deformation.

Screw hollow cooling effectively restrains thermal extension.

-

-

-

-

-