Products

-

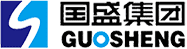

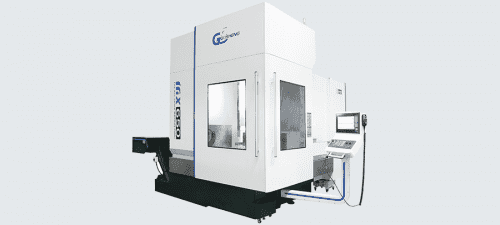

DHM HORIZONTAL MACHINING CENTER

Horizontal machining center can automatically exchange tool in the machining process, can one time clamping four surface milling, drilling, reaming, boring, reaming, tapping, and other process. The structure of the machine tool rigidity, large stroke, high precision, applicable to all kinds of heavy cutting, high precision mechanical processing field, guarantee the processing requirements of high efficiency and high precision of the single or small batch products.

-

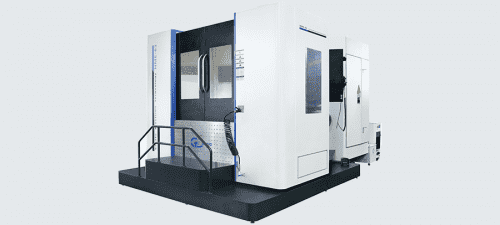

HME GENERAL HORIZONTAL MACHINING CENTER

Horizontal machining center can automatically exchange tool in the machining process, can one time clamping four surface milling, drilling, reaming, boring, reaming, tapping, and other process.The structure of the machine tool rigidity, large stroke, high precision, applicable to all kinds of heavy cutting,

-

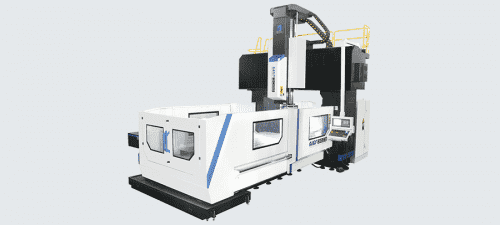

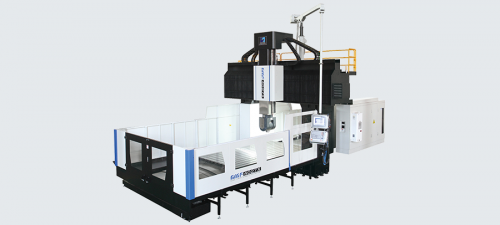

DBM HORIZONTAL BORING AND MILLING MACHINING CENTER

Horizontal machining center can automatically exchange tool in the machining process, can one time clamping four surface milling, drilling, reaming, boring, reaming, tapping, and other process. The structure of the machine tool rigidity, large stroke, high precision, applicable to all kinds of heavy cutting, high precision mechanical processing field, guarantee the processing requirements of high efficiency and high precision of the single or small batch products.

-

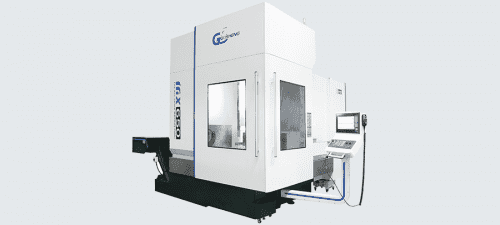

GMS DIE AND MOLD MACHINING CENTER

By means of the modern structure design methods combining the mechanical design and finite element method design, and integrating the whole machine’s thermogenic management technology and ergonomics engineering design technology, the whole machine reaches the characteristics of high rigidity, high electric rigidity, high reliability and excellent thermal stability, etc,

-

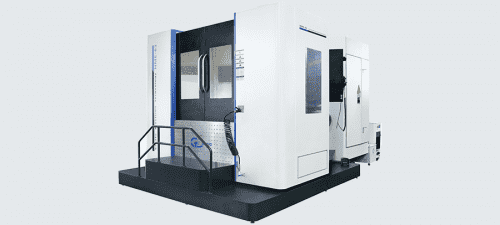

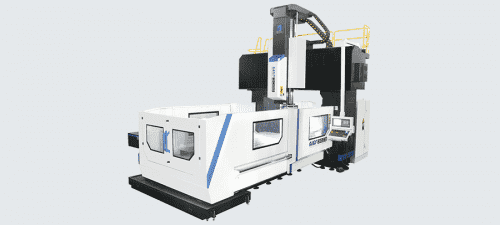

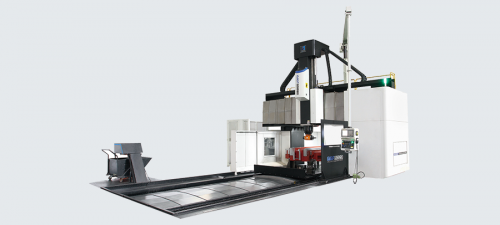

GMF GENERAL GANTRY MACHINING CENTER

Widely used in the aviation, auto, precision molding industries, GMF series can provide a high-performance mechanical system and a software interface which can be operated easily. This provides multiple choices of multiple choices that will allow you to fully realize the high precision dream.

-

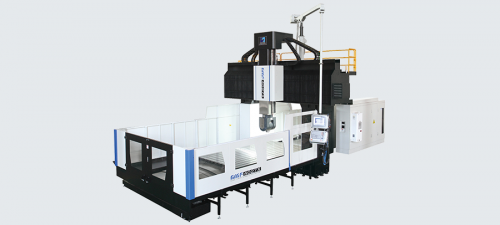

GMF 5-FACE GANTRY MACHINING CENTER

Roller-type linear rolling guide has high rigidity and high precision, which is suitable for heavy cutting.

Z axis adopts four-track or square sleeper structure, which is convenient for customers to select machine tools. Four-track is suitable for high-speed processing, and square sleeper is suitable for high-rigidity processing.

-

GMF 5-AXES GANTRY MACHINING CENTER

5-axis linkage and full-closed loop control ensure it is suitable for processing complex surfaces of precision molds.

The Z axis four wire rail structure has small friction resistance and good accuracy.

With German KESSLER AC swinging head and tuning fork type structure, AC axles are driven by torque motor.

-

GMB 5-AXES GANTRY MACHINING CENTER

5-axis linkage and full-closed loop control ensure it is suitable for processing complex surfaces of precision molds.

Z oriented box in box type symmetric structure ensures balanced cutting stress, and slight thermal deformation.

Screw hollow cooling effectively restrains thermal extension.

-

VM DIE AND MOLD MACHINING CENTER

Besides the various processing characteristics of the vertical processing center, VM series vertical mould processing center has made optimized design in both configuration and structure aiming at the features of the mould processing industry, which could satisfy the requirements of high precision, high cleanness and low heat extension when the mould contour is processed.

-

V GENERAL VERTICIAL MACHINING CENTER

Besides the various processing characteristics of the vertical machining center, V series high-speed vertical machining center has exercised optimized design aiming at the high speed and high precision requirements on the product’s processing industry on both configuration and structure.

-

MX 5-AXES VERTICAL MACHINING CENTER

5-axis linkage and full-closed loop control ensure it is suitable for processing complex surfaces of precision molds.

Using forward direction cantilever and longitudinal cradle layout, the straight axis is separated from the processing area, and the best dynamic performance and convenient operation space are obtained.

-

MVL GENERAL VERTICAL MACHINING CENTER

General Vertical Machining center, mainly used in medium-sized parts and molds, the workpiece in a fixture may be for the completion of milling, drilling, boring, reaming and other processes of processing. It can be single used and can also be used for multiple operations on parts in a production line. Cutting with powerful, high-speed positioning, mechanical and electrical integration, automatic chip control and security protection features.