Large Gantry Milling Machines

We know that we only thrive if we could guarantee our combined price tag competiveness and quality advantageous at the same time for Large Gantry Milling Machines, Cnc Milling , Vertical Milling Machine , Automatic Cnc Machine, And there are also a lot of overseas close friends who came for sight seeing, or entrust us to buy other stuff for them. You will be most welcome to come to China, to our city and to our manufacturing facility! Our corporation has been specializing in brand strategy. Customers' gratification is our greatest advertising. We also source OEM company for Large Gantry Milling Machines, We have now 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

-

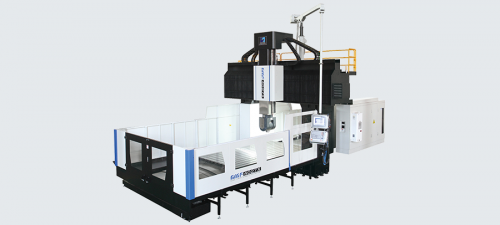

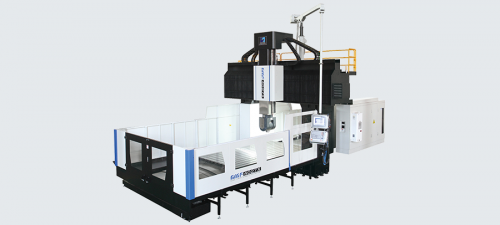

GMS DIE AND MOLD MACHINING CENTER

By means of the modern structure design methods combining the mechanical design and finite element method design, and integrating the whole machine’s thermogenic management technology and ergonomics engineering design technology, the whole machine reaches the characteristics of high rigidity, high electric rigidity, high reliability and excellent thermal stability, etc,

-

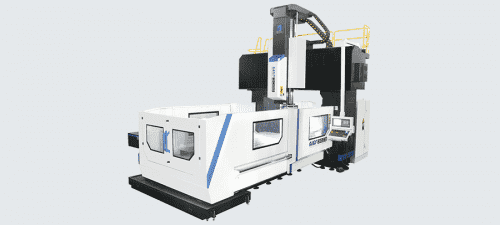

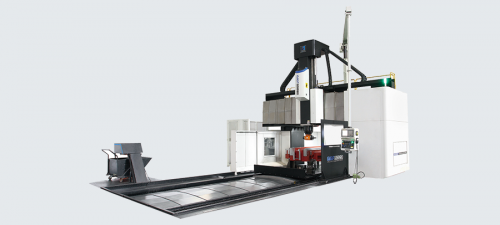

GMF GENERAL GANTRY MACHINING CENTER

Widely used in the aviation, auto, precision molding industries, GMF series can provide a high-performance mechanical system and a software interface which can be operated easily. This provides multiple choices of multiple choices that will allow you to fully realize the high precision dream.

-

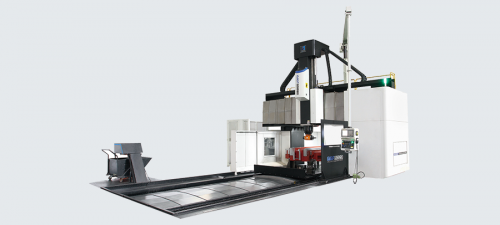

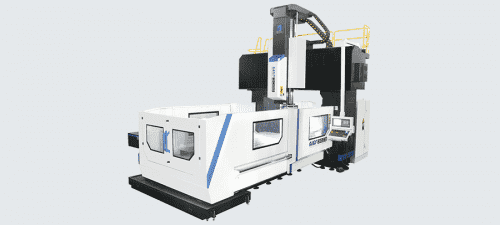

GMF 5-FACE GANTRY MACHINING CENTER

Roller-type linear rolling guide has high rigidity and high precision, which is suitable for heavy cutting.

Z axis adopts four-track or square sleeper structure, which is convenient for customers to select machine tools. Four-track is suitable for high-speed processing, and square sleeper is suitable for high-rigidity processing.

-

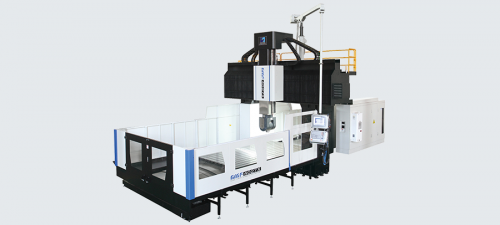

GMF 5-AXES GANTRY MACHINING CENTER

5-axis linkage and full-closed loop control ensure it is suitable for processing complex surfaces of precision molds.

The Z axis four wire rail structure has small friction resistance and good accuracy.

With German KESSLER AC swinging head and tuning fork type structure, AC axles are driven by torque motor.

-

GMB 5-AXES GANTRY MACHINING CENTER

5-axis linkage and full-closed loop control ensure it is suitable for processing complex surfaces of precision molds.

Z oriented box in box type symmetric structure ensures balanced cutting stress, and slight thermal deformation.

Screw hollow cooling effectively restrains thermal extension.

-

-

-

-

-